Boat Mold

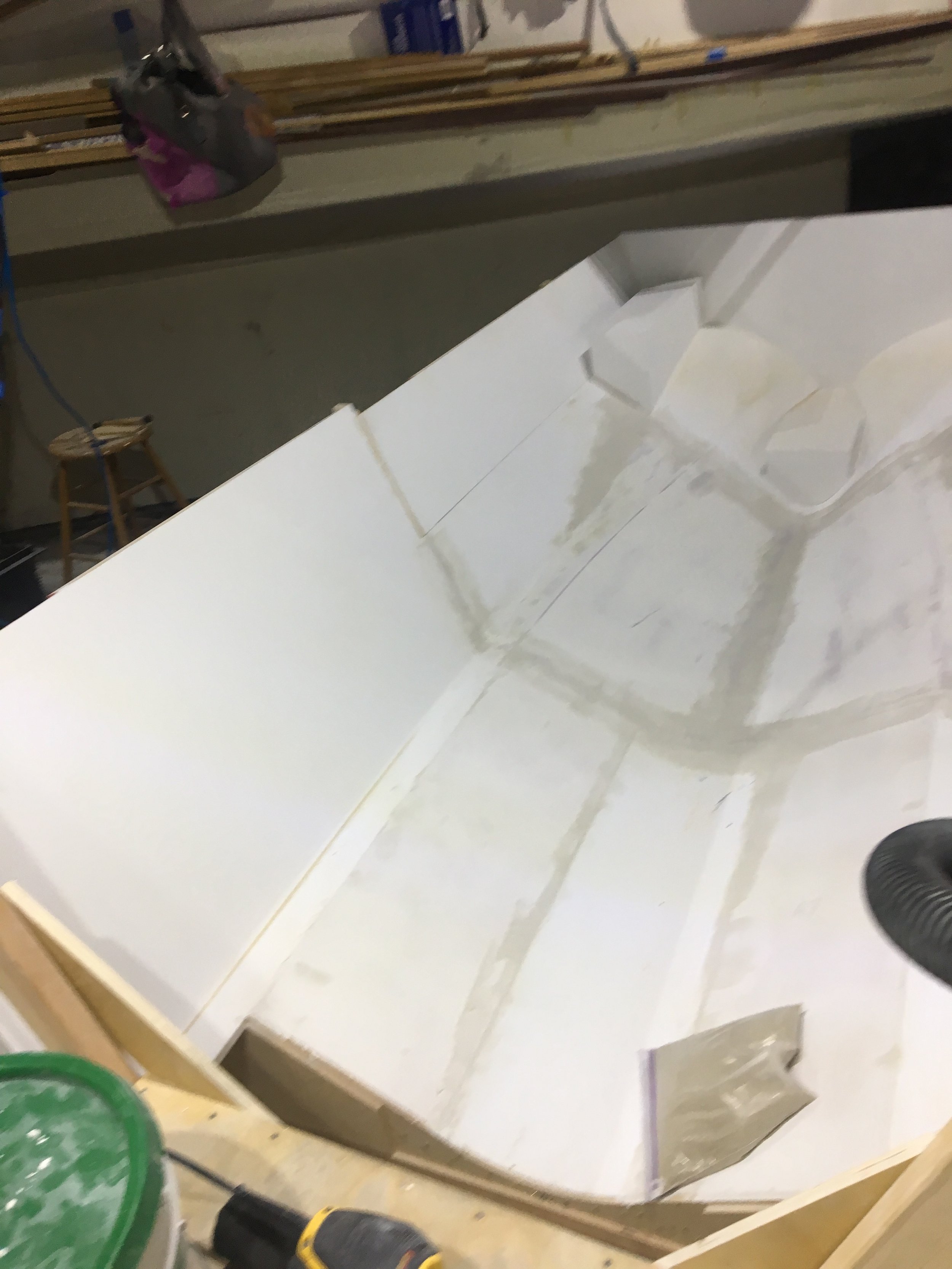

In order to make the e-glass (similar to fiberglass) into a boat with the shape I designed, I needed to make a mold, as seen below. The mold for the outer hull was made in three sections: the front, middle and back. Then, the inside mold had three sections: the front compartment, the back engine compartment, and the middle compartment.

Images of the nearly completed hull mold and a wooden scaffold on wheels that allows me to get inside and sand it.

Front Section Mold

The front mold section was entirely curved. It was made out of foam and supported by particle board. To fill all the cracks and smooth it out, I used a ton of spackle (same as used on a dry wall).

Back section Mold

The back section, thankfully, had a more flat sections where I could use particle board or MDF, but in some areas, I still need foam.

Middle Section Mold

The middle section was the simplest by far, and mostly consisted of flat surfaces.

Hull Mold Completion

After all the molds were connected and smoothed out with spackle, I sprayed on a hard epoxy-like mold paint that can be sanded to a very smooth finish. Unfortunately, this paint chemically melted some of the foam parts of the mold, so it took a few months of patching and sanding to fix the mold.

Inner Mold Middle Section

The inner mold could be mainly made out of MDF, because it only had slight curves.

Inner mold just starting to be assembled.

Inner mold mostly assembled, and all the cracks being smoothed out with spackle.

Inner mold complete and ready for e-glass (fiberglass)

CAD model of the inner molds.

Inner front compartment mold starting to be assembled.

Inner front compartment mold assembled and with fiber glass on it

See the hull construction page for details on the next steps with applying the fiber glass and finishing the hull.