Submarine Machining

The submarine was design for manufacturing resulting in mainly axisymmetric (cylindrical) parts. This was because (1.) circular seals are simpler and cheaper (2.) cylinders make good pressure vessels with uniform and lower stresses (3.) I recently converted a manual Lathe to a CNC Lathe and I was excited to uses it! Therefore the vast majority of the parts are primarily lathe parts.

Additionally there are some sheet metal parts that where laser cut and bend by sendcutsend.com as its much cheaper (material would cost more if I cut it) and easier than CNC Machining them.

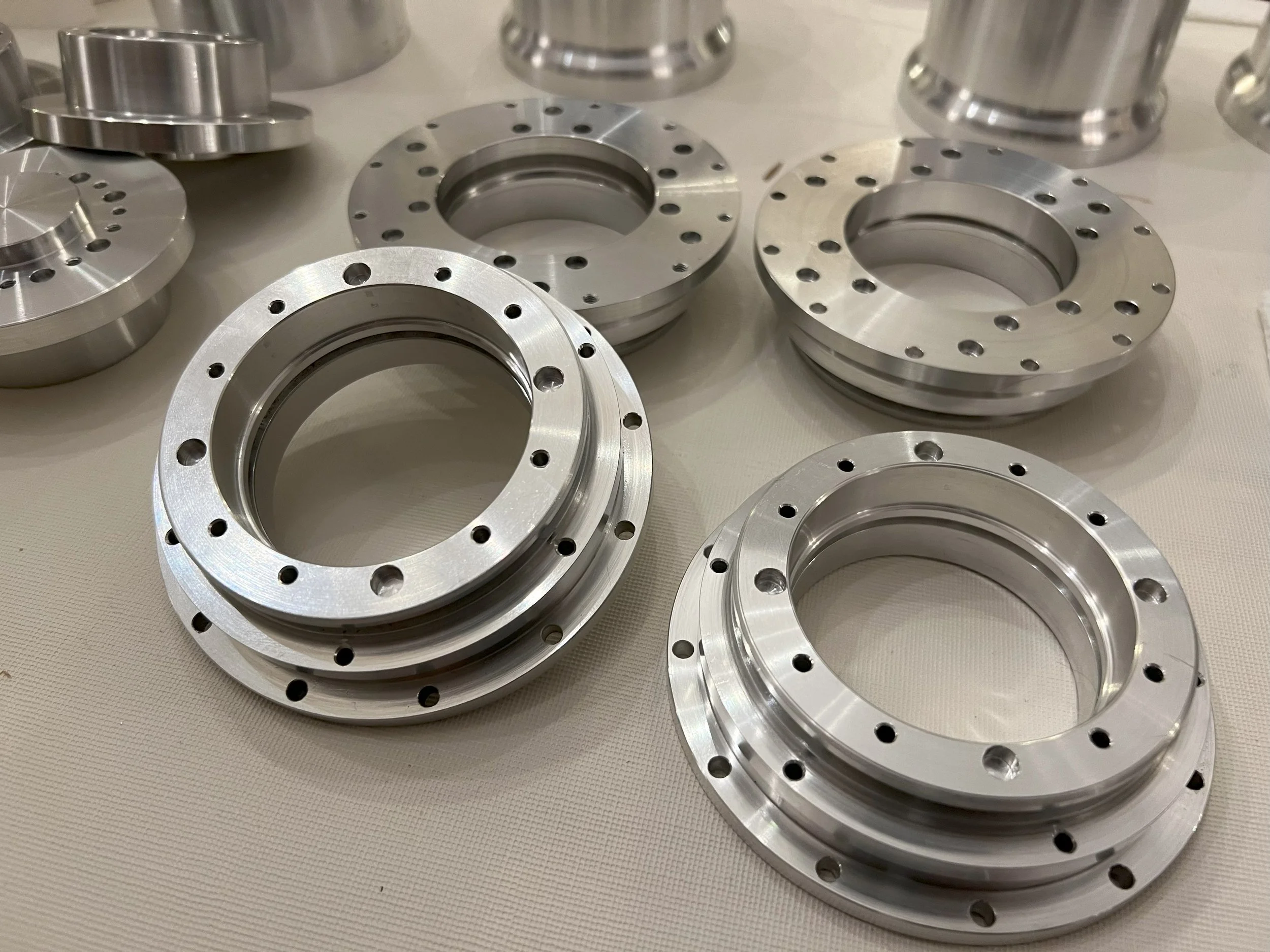

Image of 3/4of the parts I machined excluding sheet metal parts

Robot arm actuator housing flanges

Top cylinders are the robot arm actuators housing cylinders along with the weight shifter servo housing cylinder

Robot arm actuator housing output shaft

Image of the raw stock that battery caps where machined from

Anodization

To prevent corrosion of the aluminum I anodized (type 2) all the parts with some battery acid and dye. Preventing corrosion of the aluminum is particularly important as it can significantly reduce the fatigue strength of aluminum. Additionally I used a high factor of safety of 2 to reduce the risk of corrosion induce fracture.

Welding

Additionally a couple of parts where MIG welded together. Unfortunately it doesn’t look like I have any pictures right now.